A hammer is an everyday object that we use without thinking much about it. But what is the hammer’s real purpose in electrical installation? In this article, we will discuss the many uses of the hammer in electrical installation. We will also provide some useful tips to help you get the most out of your hammer!

The types of hammers used in electrical installation

There are three main types of hammers used in electrical installation: the ball peen hammer, the chisel hammer, and the claw hammer.

The ball-peen hammer and its application

The ball-peen hammer is often used in electrical installation work. The ball-peen hammer has a metal head with a rounded end and a flat end. Its handle is usually made of wood or metal. When pounding nails, always use the flat side of the hammer head. The rounded side of the head is for peening, which we will discuss later.

The ball-peen hammer can also be used for peening. Peening is a process of shaping metal by pounding it with a rounded tool. This can be useful for creating a tight seal on a joint or for shaping metal to fit a specific need.

This tool can also be used to tighten or loosen bolts. When using the ball-peen hammer for this purpose, you will want to make sure that you are using the correct size and type of bolt. You also want to be careful not to over tighten or loosen the bolt, which could damage the threads.

While the ball-peen hammer is a versatile tool, it’s important to use the right size and weight for the job at hand. A hammer that’s too heavy can damage delicate materials, while a light hammer may not have enough power to get the job done.

The chisel hammer and its application

A chisel hammer is a tool that every electrician needs. It is a specialized type of hammer designed for electrical work. The head of the chisel hammer is flat and has a slightly rounded edge. The handle is usually made of wood or plastic.

Chisel hammers can be used for a variety of tasks, including removing nails and staples, prying open boxes and panels, and scraping off old paint or insulation. In addition, chisel hammers can also be used to create pilot holes for screws and nails. Pilot holes are small holes that are drilled into a surface before a screw or nail is inserted. This helps to prevent the screw or nail from splitting the wood or damaging the surface.

The size of the chisel should be matched to the size of the nails or staples that you will be removing. For example, a small chisel hammer would not be suitable for removing large nails. Similarly, a heavy chisel hammer may be difficult to control and could cause damage to the surface you are working on.

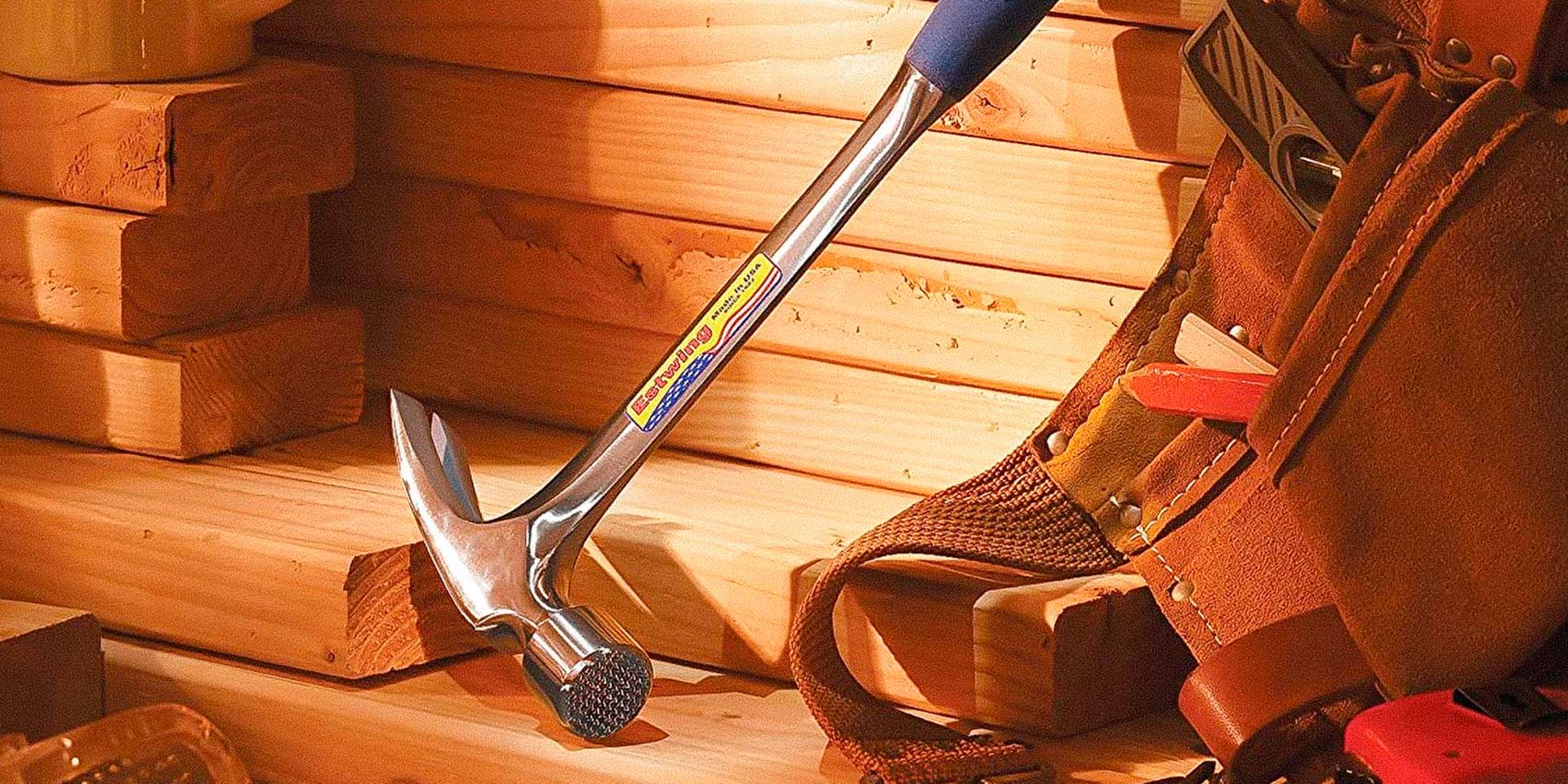

The claw hammer and its application in electrical installation

The claw hammer typically has a wooden or plastic handle with a metal head that has two claws on one side and a flat head on the other. Most claw hammers also have a magnet on the back of the head, which can be used to hold nails in place while you are working. The magnet is also handy for picking up small metal objects that you may drop while working.

It can be used for a variety of tasks, including:

- Driving nails into walls to secure electrical wiring.

- Pulling nails out of walls to remove old or damaged wiring.

- Prying open electrical boxes and junction boxes.

- Hammering in staples to secure electrical wire conduit.

When using a claw hammer for electrical installation, it is important to choose the right size and type of hammer for the job. For example, a small hammer is not going to be effective for driving nails into a concrete wall. Likewise, a heavy-duty hammer is not necessary for pulling out small nails.

Final words

When using a hammer for electrical installation, it is important to follow all safety precautions:

- Always wear gloves and eye protection when working with electricity.

- Never use a metal hammer head on live electrical wires. Use only the wooden or plastic handle to avoid shock.

- Always wear safety glasses to protect your eyes from flying debris.

- No matter what size or weight you choose, make sure that your hammer has a comfortable grip. An uncomfortable grip can lead to hand fatigue, which can make it difficult to use the hammer for extended periods of time.