So, you’re planning a digging project, maybe a garden overhaul or a new fence installation, and the last thing you want is to slice through a live electrical cable.

For electricians

How To Find Buried Electrical Wire

Delving into the ground without prior knowledge can be risky. Uncovering buried cables is not just a mere precaution but a necessary step in ensuring safety and preventing potential damages.

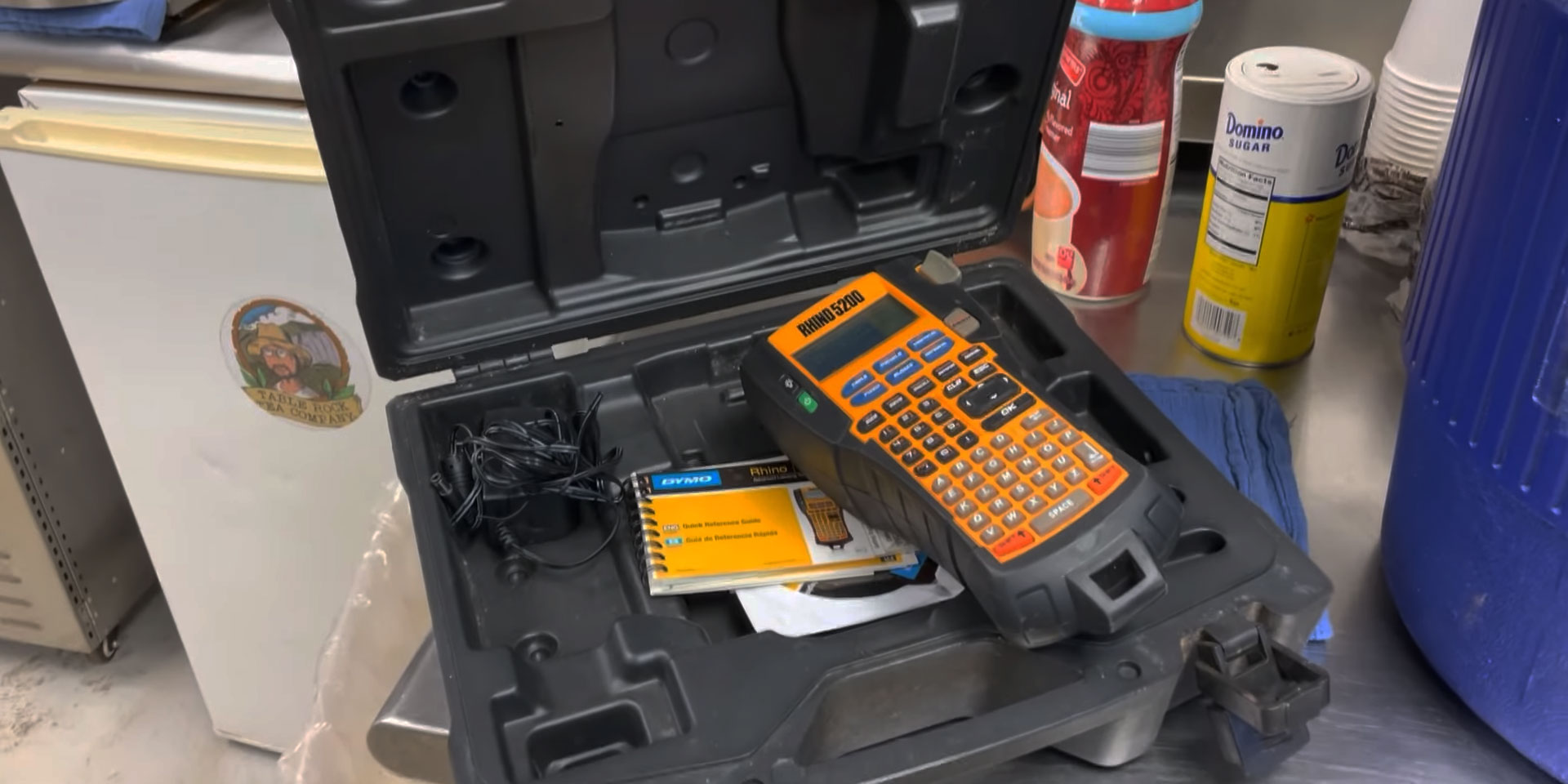

Best Electrician Label Maker Reviews

A modern label maker is an effective tool often used in various technical spheres. Electricians are among those who require such tools for labeling the wires they are working on.

Best Electricians Knife Reviews

Every day during their work, electricians face tasks that can be solved only with a certain tool. The better the tool is, the faster and more efficiently the work is done.

Best Drill for Electricians Reviews

A modern drill is a multifunctional tool with versatile technical features and specifications. It is typically used by plumbers, mechanics, and of course, electricians.

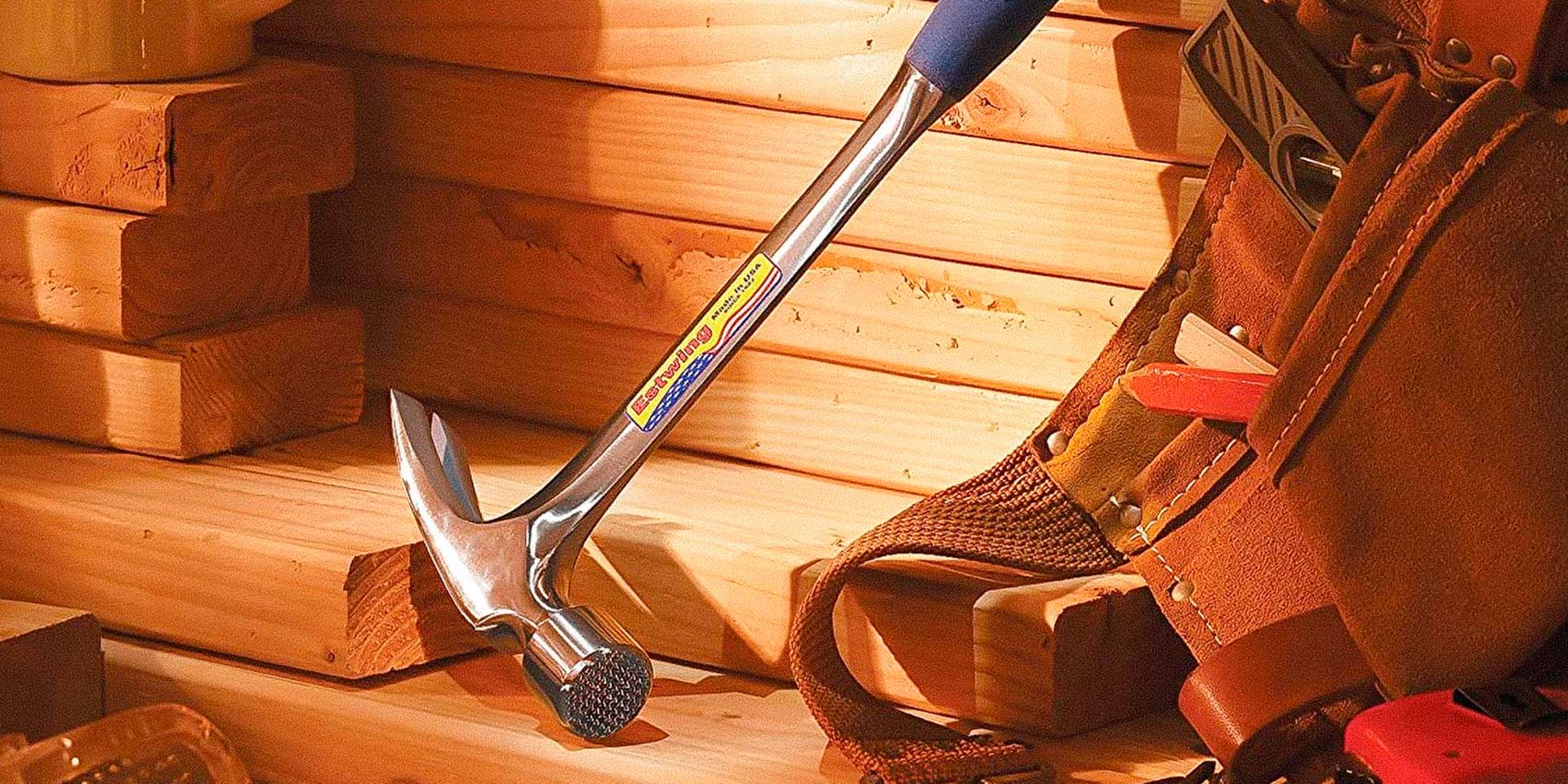

Best Hammer for Electricians Reviews

The right hammer is a must-have instrument in every electrician’s toolbox. It comes in handy when you need to remove nails & screws or connect/disconnect wires – in other words, it’ll help you pound in or tear out any electrical installations.

What Is The Use Of Hammer In Electrical Installation?

A hammer is an everyday object that we use without thinking much about it. But what is the hammer’s real purpose in electrical installation? In this article, we will discuss the many uses of the hammer in electrical installation. We will also provide some useful tips to help you get the most out of your hammer!

How Do You Protect Buried Cables?

One way to protect buried cables is to use a conduit. Conduit is tubing that encases wires and cables. It is typically made of metal or plastic. Conduit protects the wires and cables from damage, moisture, and pests.

Best Tape Measures for Electrician Review

At some point, all of us have experienced using a bad tape measure: a flimsy dirty blade, a strap not holding onto a magnet, plus a pull length is often too short for the job to be done.

What’s The Difference Between Electrical Engineer And Electrician?

When it comes to the world of electricity, there are a few key terms that everyone should know. Two of those terms are “electrical engineer” and “electrician.”

Best Tool Belt for Electricians Reviews

You do not have to be a professional electrician to realize the importance and convenience of unique tool belts. Those are not only electricians who require tool belts both for comfort and safety measures.

Best Underground Cable Locators Review

Underground cable/wire locators are devices that assist in discovering and identifying buried cables and wires. They work by emitting a signal that travels through the ground and then is picked up by the receiver.